In-House vs. Contract Manufacturing for Methylene Blue: Which is Right for You?

Neuro Blue Contract Manufacturing: Finding the Right Path for Methylene Blue Production. Methylene blue, celebrated for its remarkable versatility, plays a vital role in various fields, including medicine, advanced research, and the burgeoning cognitive wellness sector. However, understanding the intricacies of methylene blue production is essential.

As you embark on the exciting journey of incorporating methylene blue into your esteemed product line, a critical decision arises. This choice carries significant implications for the future of your venture. You face the decision between in-house manufacturing, providing hands-on control, or the opportunity to leverage the specialized expertise offered by contract manufacturers. This duality calls for a comprehensive exploration and thorough evaluation of these manufacturing pathways.

Brief overview of methylene blue's applications and the complexities involved in its production

Methylene Blue in Medicine:

Methylene blue’s medical significance is profound. It serves as a diagnostic and therapeutic tool in various procedures. From precise staining during surgeries to managing conditions like methemoglobinemia and septic shock, its role is pivotal.

Methylene blue, with its rich history and versatility, plays pivotal roles in diverse sectors, including medicine, mitochondrial health, research, and cognitive wellness. In this section, we’ll delve into its multifaceted applications and the intricate hurdles encountered in its production.

Methylene Blue in Research:

The compound’s reach extends far into research. Scientists globally rely on its unique properties, using it for cell staining, enhancing microscopic analysis, and contributing to DNA research. Laboratories universally embrace its versatility.

Methylene Blue in Cognitive Wellness:

Recent years have witnessed methylene blue gaining recognition for its potential in enhancing cognitive function and combating age-related cognitive decline. Emerging studies highlight its relevance in addressing contemporary health concerns in cognitive wellness.

Complexities in Methylene Blue Production:

Despite its broad applications, methylene blue’s production is riddled with unique challenges. The manufacturing process involves intricate stages, demanding precision and stringent adherence to quality standards. Maintaining purity and consistency is non-negotiable for diverse industries.

Furthermore, navigating the regulatory landscape adds complexity. Regulatory standards can significantly vary, complicating the production process. Successful navigation demands comprehensive industry understanding and unwavering commitment to compliance and stringent quality control measures.

Teaser about the comparison between in-house and contract manufacturing

Are you intrigued by the idea of discovering the most suitable manufacturing strategy for your business? In this comprehensive guide, we will explore the advantages and potential disadvantages of both in-house and contract manufacturing for methylene blue, including insights from Neuro Blue Contract Manufacturing. We will thoroughly investigate key factors such as cost-efficiency, quality control, scalability, and the complexities of complying with regulations in this specific context. By the time you finish reading this informative article, you will be fully equipped to navigate the intricate world of methylene blue production with confidence.

What is Methylene Blue?

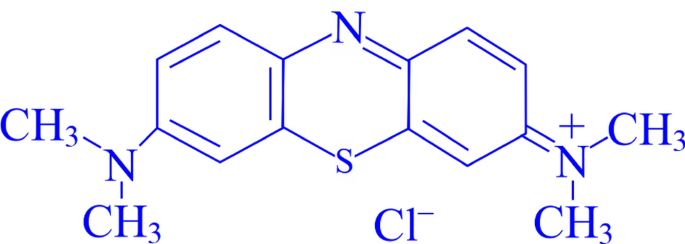

Methylene Blue, recognized for its distinct blue hue and versatile utility across diverse domains, is a chemical compound with a broad range of applications. It is commonly employed in laboratory and medical settings as a staining agent for visualizing tissues, cells, and microorganisms. Furthermore, Methylene Blue is valuable as an antidote for methemoglobinemia, a condition impairing blood oxygen transport, and it is capable of mitigating the effects of cyanide poisoning by enhancing cellular respiration. Beyond its medical role, Methylene Blue boasts a historical legacy as a textile dye and is instrumental in microscopy, bacterial staining, and mitochondrial visualization. Caution is advised in its handling and administration, especially in medical contexts, where professional guidance is recommended.

Brief history and applications of Methylene Blue

Historical Origins: Methylene Blue, a versatile compound, has its roots in the 19th century when German chemist Heinrich Caro first synthesized it. Initially, it gained fame as a textile dye, transforming the industry with its vibrant colors. Yet, its significance stretched beyond fashion due to its unique therapeutic properties.

Medical Marvel: In the field of medicine, Methylene Blue proved to be a life-saving remedy. Its ability to counteract methemoglobinemia, a condition that reduces the blood’s oxygen-carrying capacity, made it indispensable. Moreover, it became a crucial tool for staining tissues in histological examinations, enabling precise disease diagnoses.

Research Renaissance: Methylene Blue’s adaptability extended to various research pursuits. It played a pivotal role as a redox indicator in chemistry experiments, expanding scientific horizons. Additionally, it became a cornerstone in genetic and molecular biology research, facilitating groundbreaking discoveries. In neurobiology, it attracted significant attention, prompting in-depth investigations into its potential impact on neuronal function and cognitive enhancement.

The Unique Challenges of Manufacturing Methylene Blue

Methylene Blue’s exceptional utility comes with its own set of challenges, particularly in the realm of production. Manufacturers must navigate these complexities to ensure a consistent and high-quality product.

Messy Compound and Blue Stains: One of the primary challenges associated with Methylene Blue is its propensity to create blue stains. This characteristic is well-known among those who have worked with the compound, and it can pose considerable difficulties, especially in pharmaceutical and medical settings. Containing the staining effect during production and ensuring a stain-free final product can be a daunting task.

Necessity for Specialized Equipment and Protocols:

Manufacturing Methylene Blue demands a specialized approach. Due to its staining potential and chemical characteristics, it requires dedicated equipment and protocols to maintain quality and consistency. Precision is key in every step of the production process, from synthesis to formulation.

In conclusion, Methylene Blue’s rich history and versatile applications make it a substance of great importance in various fields. However, its manufacturing is not without its challenges, as it involves dealing with a compound known for its messiness and the need for specialized equipment and protocols.

Tell Us About Your Project

We look forward to the opportunity of exploring your methylene blue project together!

Contact UsThe Pros and Cons of In-House Manufacturing

In the journey of producing a groundbreaking product like Neuro Blue, a pivotal decision revolves around in-house manufacturing or outsourcing. Both approaches have their merits and drawbacks. Let’s explore the advantages and disadvantages of in-house manufacturing to aid you in making an informed choice for your cognitive wellness venture.

Cost-Efficiency in In-House Production

Initial Investment vs. Long-Term Cost Benefits

In the world of manufacturing, a critical choice emerges: in-house production or relying on external contract manufacturing. This decision pivots on managing upfront investments against potential long-term cost advantages. This section provides a thorough examination of this complex scenario, dissecting both the positives and negatives of each option. By the section’s end, you will gain essential insights to make a prudent decision that aligns with your strategic objectives and available resources.

Pros:

- Cost Management: Selecting in-house production grants precise control over production costs, reducing waste and operational expenses for improved financial efficiency.

- Adaptability: In-house production offers the flexibility to respond to market shifts and product alterations, mitigating the need for expensive external change orders.

- Quality Guarantee: Direct oversight allows the maintenance of stringent quality standards throughout production, ensuring top-notch product quality.

Cons:

- High Upfront Investment: The path to in-house manufacturing requires a substantial initial investment. This encompasses acquiring cutting-edge equipment, advanced technology, and skilled personnel, which can strain your resources.

- Ongoing Overhead: Beyond the initial investment, ongoing overhead costs come into play. These encompass expenses for facility maintenance, utilities, and employee salaries. While essential, they may impact short-term profitability and necessitate a careful financial balancing act.

- Competitive Advantage Delay: Establishing in-house manufacturing may lead to a time lag before realizing cost efficiencies. The initial phases require adjustment and fine-tuning, impacting immediate cost benefits.

Quality Control When Manufacturing In-House

In the realm of in-house production, the emphasis on quality control holds paramount importance. This section explores the profound influence of heightened oversight on ensuring the consistent excellence of Neuro Blue capsules.

Pros:

- Rigorous Quality Control: Within the in-house manufacturing setting, every production stage undergoes meticulous scrutiny. This unwavering attention guarantees that each Neuro Blue capsule adheres to stringent quality benchmarks, further enhancing the product’s overall excellence.

- Swift Issue Resolution: The direct control afforded by in-house manufacturing translates into a swift response to any quality-related concerns. This agility minimizes the risk of product recalls and customer dissatisfaction, ultimately safeguarding the company’s reputation and financial stability.

Cons:

- Resource-Intensive: Sustaining an unwavering commitment to quality control demands significant resources. This encompasses the need for highly skilled quality control personnel, advanced testing equipment, and a substantial financial investment.

- Potential Tunnel Vision: A singular focus on internal processes can inadvertently restrict exposure to external best practices and innovative approaches. Striking a balance becomes imperative to ensure continued growth and adaptation in a dynamic industry landscape.

Scalability Concerns for In-House Manufacturing

The process of scaling up production is a pivotal phase within in-house manufacturing. This section delves into the nuanced aspects of managing scalability concerns, shedding light on the benefits and complexities associated with this critical undertaking.

Pros:

- Initial Command: In the realm of in-house manufacturing, you retain complete control over the production process. This control ensures that the initial Neuro Blue batches align meticulously with your exacting standards, fostering unwavering product consistency and quality.

- Confidentiality: In-house manufacturing affords the invaluable advantage of keeping sensitive formulations and processes securely within your organization’s boundaries. This approach significantly mitigates the risk of intellectual property leaks, bolstering data security.

Cons:

- Capacity Constraints: Scaling up in-house manufacturing is not without its challenges. It often demands a substantial investment of time and effort. These challenges can result in production bottlenecks, potentially impacting delivery schedules and market responsiveness.

- Resource Demands: As production scales, the demand for critical resources such as space, labor, and equipment significantly intensifies. Meeting these heightened requirements often necessitates substantial additional investments, impacting both financial resources and operational efficiency.

In summary, deciding between in-house and outsourcing for Neuro Blue manufacturing involves a meticulous assessment of advantages and disadvantages. While it offers advantages like cost management, rigorous quality control, and confidentiality, it entails a significant initial investment and challenges in scaling production to meet growing demand. Ultimately, the choice hinges on your specific goals and resources, and comprehending these key factors is pivotal to the success of your cognitive wellness venture.

The Advantages of Contract Manufacturing

As you embark on the journey to produce Neuro Blue with precision and efficiency, it’s essential to comprehensively examine the strategic advantages that contract manufacturing brings to the table. This section offers an in-depth exploration of the multifaceted benefits associated with opting for contract manufacturing in the realm of cognitive wellness. These advantages encompass various facets. From cost-efficiency and quality assurance to scalability and regulatory compliance, they provide you with a comprehensive understanding of the strategic prowess of this manufacturing approach.

Expertise in Methylene Blue Production

Contract manufacturers offer a wealth of specialized knowledge and experience that significantly benefit the production of Neuro Blue capsules. Here, we outline the key advantages of their expertise:

Specialization and Experience in Avoiding Blue Staining:

- Contract manufacturers possess specialized expertise and extensive experience in formulating compounds like methylene blue.

- This specialized knowledge is invaluable when dealing with methylene blue’s unique challenges, particularly the risk of staining.

Effective Problem-Solving:

- Contract manufacturers have honed their skills and processes to effectively address challenges related to methylene blue production.

- They possess in-depth knowledge of formulating and producing methylene blue-based products without staining issues, ensuring the highest quality Neuro Blue capsules.

Stringent Quality Control:

- Their experience translates into stringent quality control measures.

- Each Neuro Blue capsule undergoes meticulous scrutiny to meet the highest quality standards, instilling consumer confidence in product consistency and effectiveness.

In conclusion, the partnership with contract manufacturers not only enhances the production process but also fortifies the reputation of Neuro Blue as a premium cognitive wellness solution. It’s a collaborative journey where expertise, experience, and excellence converge to create a product that stands out in the realm of cognitive wellness.

Flexibility and Scalability with Contract Manufacturers

Flexibility and scalability are pivotal in the manufacturing landscape, particularly for products like Neuro Blue, which experience variable demand. Here, we present the ways in which contract manufacturers excel in adapting to changing demand:

Adaptive Production Levels:

- Contract manufacturers possess a unique level of flexibility and scalability, tailored to products with fluctuating demand like Neuro Blue.

- They can swiftly adjust production levels as needed, a hallmark of contract manufacturing.

Agile Response to Demand Fluctuations:

- Partnering with contract manufacturers grants you a production partner capable of quickly adapting to changing demand scenarios.

- Whether confronted with increased demand or temporary decreases, contract manufacturers efficiently respond without significant investments in additional facilities or personnel.

Streamlined Supply Chain:

- This adaptability not only ensures production continuity but also streamlines the supply chain.

- Your cognitive wellness venture remains agile and responsive to market shifts, enhancing its competitive edge.

Cost-Efficiency as a Cornerstone:

- The cost-effectiveness of contract manufacturing stands as a notable advantage.

- You pay solely for the production capacity required, alleviating the burden of maintaining underutilized facilities or overextending resources during peak-demand periods.

- This cost-efficient approach aligns with resource management best practices, contributing to the overall success and profitability of your venture.

In conclusion, the partnership with contract manufacturers is more than a collaboration; it’s a strategic advantage. They embody adaptability, efficiency, and cost-effectiveness, ensuring that Neuro Blue and similar cognitive wellness products meet market demands with excellence while safeguarding the bottom line. It’s a partnership that empowers your venture to thrive and excel in the ever-evolving landscape of cognitive wellness.

Regulatory Compliance Made Easier

In the intricate landscape of health and wellness regulations, navigating the path to market can be a daunting challenge. Here, we delve into the invaluable regulatory expertise offered by contract manufacturers and how it significantly benefits Neuro Blue’s journey:

Regulatory Acumen of Contract Manufacturers:

- Contract manufacturers bring substantial regulatory knowledge to the forefront, acting as a pivotal asset for Neuro Blue’s production and market entry.

- Their profound familiarity with industry-specific regulations and compliance standards simplifies the intricate process of meeting essential requirements.

Streamlining Regulatory Processes:

- Contract manufacturers’ expertise not only simplifies but also expedites Neuro Blue’s journey to the market.

- Their comprehensive understanding of regulatory intricacies paves the way for a smoother journey, effectively reducing the risk of obstacles and delays.

Facilitating Swift Market Entry:

- By partnering with contract manufacturers, you gain a trusted ally well-versed in the nuances of regulatory compliance.

- This expertise translates into streamlined processes that facilitate adherence to all pertinent guidelines and standards.

Ensuring Stringent Adherence to Guidelines:

- Contract manufacturers play a pivotal role in ensuring that Neuro Blue maintains unwavering adherence to all relevant guidelines and standards.

- Their steadfast commitment to regulatory compliance stands as a safeguard, ensuring the product’s integrity and market readiness.

In conclusion, collaborating with contract manufacturers isn’t merely a partnership; it’s the solution to navigating the complexities of health and wellness regulations. It ensures Neuro Blue not only meets but surpasses compliance standards, establishing itself as a reputable choice in the cognitive wellness landscape.

In summary, when contemplating the choice between in-house and contract manufacturing for Neuro Blue production, it’s vital to recognize that contract manufacturing offers a wide array of advantages. These encompass specialized expertise in methylene blue production and stringent quality control measures. Additionally, they entail flexibility and scalability to adapt to fluctuations in demand. Moreover, you gain access to expert guidance for navigating the intricate regulatory landscape. Collaborating with a contract manufacturer emerges as a strategic and beneficial decision for your cognitive wellness venture, a conclusion reached through a comprehensive evaluation detailed in “Neuro Blue Contract Manufacturing.

Case Study: The Neuro Blue Capsule Product

In this comprehensive analysis, we embark on an insightful journey into the innovative realm of the Neuro Blue capsule product. Throughout this exploration, we uncover the pioneering features, the intricate development process, and the strategic decisions intricately woven into Neuro Blue’s exceptional success story within the competitive cognitive wellness market. This case study stands as a prime illustration of the fundamental principles discussed in the detailed guide.

Eliminating the Blue-Stained Mouth Issue

How Neuro Blue’s unique encapsulation process eliminates traditional issues with methylene blue like staining

Our journey commences with a closer look at one of Neuro Blue’s most notable features – its revolutionary solution to a long-standing issue associated with methylene blue consumption: staining. In this section, we delve into the encapsulation process that skillfully eradicates the conventional problem of blue staining.

Traditional methods of methylene blue consumption, frequently in tincture form, have long been plagued by the unsightly issue of blue staining. This concern has dissuaded numerous potential users from reaping the cognitive benefits of methylene blue.

Neuro Blue’s innovative encapsulation process reimagines this experience. By enclosing key ingredients, including methylene blue, within each Neuro Blue capsule, the staining predicament becomes a relic of the past. This pioneering approach empowers users to savor the cognitive enhancements without apprehension about unappealing blue discoloration, positioning Neuro Blue as an exceptional and distinct product.

Furthermore, the encapsulation process guarantees precise dosage and maximizes the bioavailability of essential ingredients. This meticulous attention to detail elevates the overall user experience and underscores Neuro Blue’s steadfast commitment to quality and efficacy.

Partnering with a Specialized Contract Manufacturer

How this added unique value and ensured a quality product

Shifting our focus to the hidden narrative of Neuro Blue’s triumph, we uncover a strategic partnership with a specialized contract manufacturer. This collaboration united Neuro Blue’s visionary concept with the contract manufacturer’s extensive expertise in producing compounds like methylene blue.

The contract manufacturer’s invaluable expertise played a pivotal role in refining the encapsulation process. Their specialized knowledge addressed the distinct challenges associated with methylene blue production, ultimately contributing to the eradication of staining while upholding the highest standards of quality.

Moreover, the collaboration with the contract manufacturer bestowed upon Neuro Blue the advantage of adaptability and scalability. This agile response to evolving demand dynamics ensured an uninterrupted supply chain, all while optimizing resource utilization.

Essentially, the examination of the Neuro Blue capsule product serves as a tangible illustration that resonates with the fundamental concepts presented in our comprehensive guide. This thorough investigation uncovers a story interwoven with innovative encapsulation techniques and successful partnerships with experienced contract manufacturers. These collaborative elements adeptly addressed long-standing concerns associated with methylene blue usage, resulting in the creation of an outstanding product in the cognitive wellness domain.

Key Factors to Consider When Making Your Choice

As you navigate the intricate landscape of Neuro Blue’s production, it’s vital to conduct a thorough evaluation of critical factors. This meticulous examination, informed by insights from our comprehensive guide, serves as the bedrock of your decision-making process. The effectiveness and success of your manufacturing efforts pivot on this well-thought-out choice. In this section, we embark on an exhaustive exploration of pivotal considerations, shedding light on your path and ensuring that your decision aligns seamlessly with your vision for Neuro Blue Contract Manufacturing.

Assess Your Production Volume Needs

Small vs. Large Scale Production: Finding the Right Fit

In the process of determining the most suitable manufacturing approach for Neuro Blue, an essential aspect to ponder is the production scale aligned with your unique vision. Your required production volume significantly influences your choice of manufacturing method. It demands a thoughtful consideration of whether your strategy leans towards a smaller, specialized production model or a larger, more extensive operation.

To arrive at a well-informed decision, it’s imperative to consider multiple facets. Commence by evaluating the expected demand for Neuro Blue, the scope of your market reach, and the resources at your disposal. Additionally, delve into the intricacies of potential growth trajectories and scalability. These thorough assessments will establish a robust foundation for your selection of the manufacturing method that best aligns with your goals and requirements.

Evaluate Your Quality Control Requirements

How much oversight is needed?

In the context of Neuro Blue production, where precision and consistency are paramount, quality control assumes a pivotal role. It becomes imperative to gauge the level of oversight and quality control that your product demands. This assessment should consider various factors, including the intricacies of production, the rigidity of quality standards, and the complexities of regulatory compliance.

To make a well-informed decision, delve deeply into the specific requirements of your product. Evaluate the intricacies and potential challenges that may arise during production. Scrutinize the quality standards that must be upheld, ensuring that they align seamlessly with your product’s goals. Additionally, consider the regulatory landscape and the adherence necessary for compliance.

Understand the Financial Implications

Short-term vs long-term costs

The financial dimension of choosing between in-house and contract manufacturing bears profound significance. To make a well-informed decision, a comprehensive evaluation of short-term and long-term costs is paramount. It commences with a meticulous examination of the upfront investments required for in-house production, which encompasses a wide spectrum of expenses, including equipment procurement, staffing, and facility setup. These initial outlays must be weighed against the financial commitments associated with collaborating with a specialized contract manufacturer.

Furthermore, it’s crucial to consider dynamic factors such as economies of scale, production efficiency, and the potential for long-term cost savings. Striking an optimal equilibrium between these upfront investments and long-term profitability emerges as a central tenet in making a judicious and fiscally prudent decision. This intricate financial analysis forms a cornerstone of the decision-making process, allowing you to navigate the complex landscape of methylene blue production with confidence and fiscal acumen.

This comprehensive assessment offers valuable insights into the specific quality control needs of your Neuro Blue project. It forms the foundation for making an informed decision, drawing from the extensive guide’s insights. Your choice may lean towards in-house production with careful oversight or involve partnering with a reputable contract manufacturer known for their stringent quality standards in Neuro Blue Contract Manufacturing.

Conclusion

To summarize our extensive examination, let’s revisit the crucial insights that can guide your choice between in-house manufacturing and partnering with a contract manufacturer, such as Neuro Blue Contract Manufacturing, for methylene blue-based products like Neuro Blue capsules.

Summary of Key Points

We’ve unveiled crucial factors that influence your decision:

- Production Volume Needs: Your choice hinges on demand and resources, ranging from small-scale to extensive operations.

- Quality Control Requirements: Contemplate complexity, standards, and compliance to determine the level of oversight required.

- Financial Implications: Strike a balance between short-term investments and long-term gains, taking into account equipment, personnel, and facility costs.

A final takeaway on how to choose between in-house and contract manufacturing for methylene blue

In the realm of methylene blue-based products, there’s no one-size-fits-all solution. Your decision should be a reflection of your vision, your product’s unique requirements, and considerations related to efficiency, cost, and quality.

As you embark on this journey, it’s crucial to understand that the choice you make will have a substantial impact on the success of your product. Whether you opt for the meticulous control of in-house manufacturing or leverage the expertise of a specialized contract manufacturer like Neuro Blue Contract Manufacturing, ensure your decision is well-informed, drawing from insights offered in the comprehensive guide.